Vibrant Series

VERTICAL MACHINING CENTER

Vibrant Series

Model Variants

- Vibrant 400

- Vibrant 500

- Vibrant 600

- Vibrant 700

- Vibrant 800

- Vibrant 900

- Vibrant 855 Super

- Vibrant 1166

- Vibrant 1366

Our new generation Vertical Machining Centers are incorporate a wide range of enhancements and available with a myriad of options to choose from. The modular machine portfolio and sophisticated engineering knowledge that enables us to deliver optimized solutions with optimal performance that make Macpower VMCs better than ever before.

Overview

RIGID Structure & Frame

Sturdiness of the foundation determined the soundness of the structure. The major construction parts are based on FG260 grade cast iron, to ensure optimum harmonic stability and maximum damping during cutting. Base and column are reinforced with heavy ribs for stability and least distortion. The uniform dense, fine graded casting distributed stress and heat throughout the machine structure.

High Capacity Accurate Spindle

The precision cartridge spindle unit having three super precise angular contact bearings at front and two at rear end, this combination ensures higher stiffness. Bearings are perfectly aligned and grease packed for long life. Spindle is indirectly driven by high speed AC spindle motor with reduced pulley ratio, to achieve high spindle torque and optimal performance of machine.

Double Anchored Ball Screws

Ball Screws are directed by direct coupled AC servo motor with flexible coupling. This greatly improves positioning accuracy, and provides more accurate threading and contouring. Ball Screws are anchored at both ends and inspected for parallelism with axis guide. Pre-loaded ball nuts eliminate backlash.

Heavy duty roller LM guideways

All axes are furnished with precise and heavy load capacity re-circulating roller guide ways enabling high acceleration-de acceleration and hence better rigidness.

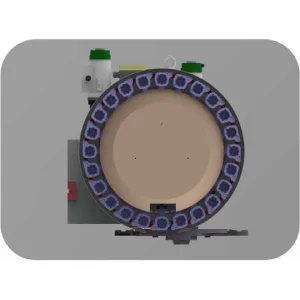

Reliable ATC

Twin arm type side mounted ATC driven by screw and cam speed up tool changing time with random access and resulted in reduce cycle time and higher productivity. Each subsystem is tested for innumerable cycle at every stage to enhance reliability.

Advance Inspection Technology

Laser Calibration is carried out to insure the linear accuracy, providing accurate compensation for pitch and backlash. The machine facilities the attainment of positional accuracy up to 0.01 mm / 300 mm and repeatability accuracy up to 0.007 mm.

Standard Accessories

- Roller Guide Ways

- 24 Tool ACT

- Work Light

- Hand Weel

- Leveling PAD

- Ring Coolant

- Patrol Light

- Air Gun

- Centralized Lubrication System

- Pull Stud

- Dry Air Cutting

Optional Accessories

- Coolant Gun

- Auto Door

- Chip Conveyor

- Linear Scale

- Stabilizer

- Flush Coolant

- Coolant Through Spindle

- 30 Tools ATC

- Rotary Table

- Rotary Tilting Table

- Gear Box

- Higher RPM Spindles

- Spindle Chiller

- Indexer

- Tool Probe

- Dry Air

- Tooled Up Solutions

- Vertical Axis Pull Up During Power Failure

Machine Output

Technical Specifications

Capacity

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| X Axis Travel | mm | 410 | 525 | 600 | 700 | 800 | 900 | 850 | 1100 | 1310 |

| Y Axis Travel | mm | 300 | 500 | 500 | 500 | 550 | 550 | 510 | 650 | 650 |

| Z Axis Travel | mm | 300 | 500 | 500 | 500 | 550 | 550 | 510 | 650 | 650 |

| Rapid Feed Rates X/Y/Z Axis | m/min | 30/30/30 | 30/30/30 | 30/30/30 | 30/30/30 | 30/30/30 | 30/30/30 | 30/30/30 | 30/30/24 | 24/24/20 |

| Distance From Table Top To Spindle Face | mm | 100-400 | 100-600 | 100-600 | 100-600 | 100-650 | 100-650 | 100-610 | 140-790 | 140-790 |

Slides

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| Table Size (Clamping Area) | mm | 300X600 | 450X650 | 500X800 | 500X900 | 500X1000 | 500X1100 | 500X1050 | 600X1300 | 650X1450 |

| No./Width/VD of T-Slots | mm | 2/14/100 | 3/18/125 | 4/18/100 | 4/18/100 | 4/18/100 | 4/18/100 | 4/18/100 | 5/18/100 | 5/18/100 |

| Max Safe Load on Table | KG | 250 | 500 | 500 | 550 | 600 | 900 | 800 | 1100 | 1300 |

Main Spindle

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| Taper | - | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT50 | BT50 |

| Speed | RPM | 80-8000 | 80-8000 | 80-8000 | 80-8000 | 80-8000 | 80-8000 | 80-8000 | 80-8000/60-6000 | 80-8000/60-6000 |

| Cutting Feed Rate | mm/min | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Rated Power (Fanuc) | KW | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 | 7.5/11 | 7.5/11 | 7.5/11 | 11/15 | 11/15 |

Auto Tool Changer

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| Type | - | Twin Arm | Twin Arm | Twin Arm | Twin Arm | Twin Arm | Twin Arm | Twin Arm | Twin Arm | Twin Arm |

| No. of Tools | - | 20 | 24 | 24 | 24 | 24 | 24 | 24 | 24/20 | 24/20 |

| Tool Selection | - | RANDOM | RANDOM | RANDOM | RANDOM | RANDOM | RANDOM | RANDOM | RANDOM | RANDOM |

| Max. Tool Dia. (Pocket Full Empty) | mm | 80/150 | 80/150 | 80/150 | 80/150 | 80/150 | 80/150 | 80/150 | 80/150,125/200 | 80/150,125/200 |

| Tool Length | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300/400 | 300/400 |

| Tool Weight | Kg | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7/20 | 7/20 |

Accuracy

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| Positioning | mm | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Repeatability | mm | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 | 0.007 |

Installation Data

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| Pneumatic Supply | Bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Machine Weight (Approx) | Kg | 3150 | 4060 | 4360 | 4400 | 4800 | 5040 | 5500 | 7170/(7860) | 7405/8095 |

| Total Connected Load | KVA | 16 | 16 | 16 | 16 | 19 | 19 | 19 | 25 | 26 |

| Power Supply | - | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. | AC 440 V, 50HZ, 3 Ph. |

| Machine Dimensions (WSDSH) (Approx) | mm | 1911 X 2618 X 2500 | 2332 X 2845 X 2890 | 2332 X 2845 X 2890 | 2407 X 2845 X 2890 | 2602 X 2842 X 2878 | 2677 X 2842 X 2878 | 2570 X 3168 X 3057 | 2990 X 2570 X 3290(BT 40) 2990 X 3380 X 3375(BT 50) | 3590 X 2570 X 3320(BT 40) 3590 X 3380 X 3405(BT 50) |

System

| DESCRIPTION | UNIT | Vibrant 400 | Vibrant 500 | Vibrant 600 | Vibrant 700 | Vibrant 800 | Vibrant 900 | Vibrant 855 Super | Vibrant 1166 | Vibrant 1366 |

|---|---|---|---|---|---|---|---|---|---|---|

| Fanuc | - | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS | 0I MF PLUS |

| SIEMENS Siemens | - | 828D | 828D | 828D | 828D | 828D | 828D | 828D | 828D | 828D |

| Mitsubishi | - | M 80 V | M 80 V | M 80 V | M 80 V | M 80 V | M 80 V | M 80 V | M 80 V | M 80 V |