GX Series

Turning Center

GX Series

Model Variants

- GX 100 JUNIOR

- GX 100 JUNIOR PLUS

- GX 100 SUPER

- GX 200 SUPER

In today’s competitive market, you need robust CNC turning centers with uncompromised performance and specifications to produce world class products quickly accurately and with minimum non productive time.

Overview

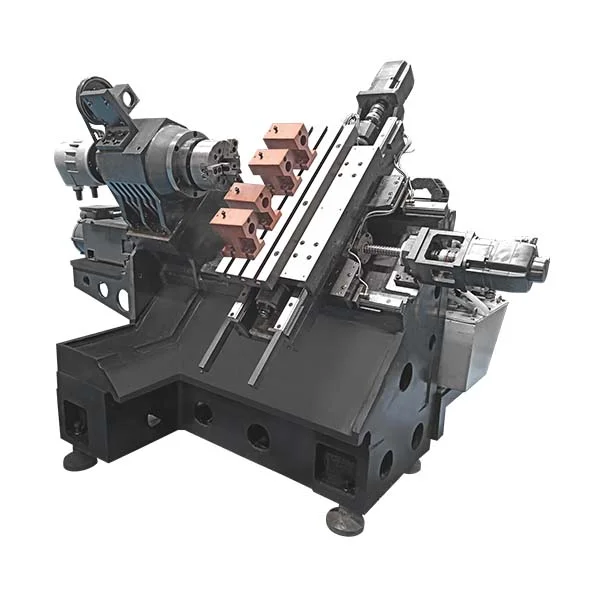

Structure & Frame

Single piece monoblock structure is made out of grade 25 cast iron for more stability. It is heavily ribbed to provide more rigidity and less distortion during heavy cuts and faster production, with virtually no vibration. Structure also facilitates easy chip disposal. Also the footprint has been reduced to save valuable space at customer’s end.

Carriage Assembly

X and Z Slide are mounted on precise four circuit linear motion blocks with high load carrying capacity, designed to support increased acceleration and deceleration rates as well as cutting pressure.

Guarding

Equipped with the advantage of an ergonomic design. The machine comes with a full guard that enables a clean premise throughout the operation. These feature prevents contamination being spread on to machine slides, switches and other electrical devices.

Spindle

The spindle is of cartridge type design and uses 3 super precision angular contact bearings at front and 2 angular contact bearings at rear end. The bearing configuration gives high stiffness to the spindle assembly in both axial and radial direction.

Precise Roller Guideways

All axes are furnished with precise and heavy load capacity re-circulating roller guide ways enabling high acceleration-de acceleration and hence batter productivity.

Double Anchored Ball Screws

Ball Screws are directed by direct coupled AC servo motor with flexible coupling. This greatly improves positioning accuracy, and provides more accurate threading and contouring. Ball Screws are anchored at both ends and inspected for parallelism with axis guide. Pre-loaded ball nuts eliminate backlash.

Linear Tooling

Linear Tooling helps in faster production by reducing overall cycle time thereby improving productivity at large and helps in reducing cost per component for the customer.

Advance Inspection Technology

Laser Calibration is carried out to insure the linear accuracy, providing accurate compensation for pitch and backlash. The machine facilities the attainment of positional accuracy up to 0.010 mm / 300 mm and repeatability accuracy up to 0.007 mm.

Heavy duty roller LM guideways

All axes are furnished with precise and heavy load capacity re-circulating roller guide ways enabling high acceleration-de acceleration and hence better rigidness.

Standard Accessories

- Roller Guide Ways

- AC Spindle Drive & AC Servo Drive

- Hydraulic Chuck with Actuating Hollow Cylinder

- Hydraulic Unit

- Coolant System

- Centralized Lubrication System

- Axial & Radial Blocks

- Boring Bar Blocks

- Patrol Light

- Foot Switch

Optional Accessories

- Chip Conveyor

- Bar Feeder

- Stabilizer

- Hydraulic Collet Chuck

- Auto Door

- Oil Skimmer

- Steady Rest

- Tooled Up Solution

- Tool Probe

- Work Probe

Machine Output

Technical Specifications

Capacity

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| Standard Turning Dia. | mm | Ø 90 | Ø 90 | Ø 100 | Ø 200 |

| Maximum Turning Dia.* | mm | Ø 135 | Ø 135 | Ø 165 | - |

| Swing Over Bed | mm | Ø 150 | Ø 150 | Ø 300 | Ø 500 |

| Maximum Turning Length | mm | 150 | 150 | 200 | 200 |

Slides

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| Cross (X-axis) Travel | mm | 250 | 250 | 360 | 360 |

| Longitudinal (Z-axis) Travel | mm | 150 | 150 | 200 | 200 |

| Rapid Feed (X axes) | m/mm | 24 | 24 | 24 | 24 |

| Rapid Feed (Z axes) | m/mm | 24 | 24 | 24 | 24 |

Main Spindle

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| Spindle Nose | - | A2-4 | A2-5 | A2-5 | A2-6 |

| Spindle Bore | mm | 40 | 54 | 54 | 63 |

| Max. Bar Capacity | mm | 25 | 42 | 42 | 51 |

| Chuck Size | mm | Ø 135 x 3 Jaw | Ø 165 x 3 Jaw | Ø 165 x 3 Jaw | Ø 200 x 3 Jaw |

| Speed Range | rpm | 50 - 5000 | 50 - 4000 | 50 - 4000 | 50 - 3500 |

| Full Power Range | rpm | 1000 - 2867 | 1000 - 2867 | 1000 - 3000 | 1000 - 3000 |

| Spindle Motor (Continues Rating) | kw | 3.7 / 5.5 | 3.7 / 7.5 | 5.5 / 7.5 | 7.5 / 11 |

| Spindle Motor (15min. Rating) | kw | 3.7 / 5.5 | 3.7 / 7.5 | 5.5 / 7.5 | 7.5 / 11 |

Tooling Arrangement

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| No. of Tools | No. | 5 | 5 | 5 | 5 |

| Tool Size | mm | 20 x 20 | 20 x 20 | 25 x 25 | 25 x 25 |

| Max. Boring Bar Capacity | mm | 25 | 25 | 32 | 40 |

Accuracy

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| Positioning Accuracy | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Repeatability | mm | 0.007 | 0.007 | 0.007 | 0.007 |

Other Data

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| Weight (Approx.) | kg. | 2000 | 2100 | 2500 | 2600 |

| Dimensions (L x W x H)(Approx.) | mm | 2385 x 1455 x 1525 | 2385 x 1455 x 1525 | 2550 x 1560 x 1770 | 2550 x 1560 x 1770 |

System

| DESCRIPTION | UNIT | GX-100 JUNIOR | GX-100 JUNIOR PLUS | GX-100 SUPER | GX-200 SUPER |

|---|---|---|---|---|---|

| Fanuc | - | OI TF PLUS | OI TF PLUS | OI TF PLUS | OI TF PLUS |

| Siemens | - | 808 D | 808 D | 828 D | 828 D |