- Home

- About Us

- Infrastructure

- Products

- Investor Forum

- Public Offer Documents

- Annual Report & Financials

- Investor Presentation

- Transcript

- Shareholding Pattern

- Press Release

- Policies

- Board & Committee Details

- Contact for Investor

- Media Coverage

- SEBI Circular

- Compliance Under Regulation

- Stock Exchange Fillings

- Annual Return

- Annual Secretarial Compliance Report

- Investor Information

- CSR Report

- News Paper Advertisement

- Events

- Get in Touch

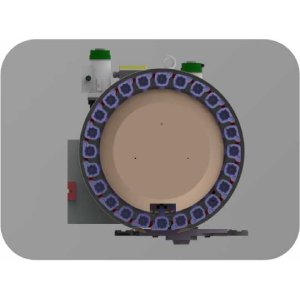

High Capacity Accurate Spindle

The precision cartridge spindle unit having three super precise angular contact bearings at front and two at rear end, this combination ensures higher stiffness. Bearings are perfectly aligned and grease packed for long life. Spindle is indirectly driven by high speed AC spindle motor with reduced pulley ratio, to achieve high spindle torque and optimal performance of machine.