- Home

- About Us

- Infrastructure

- Products

- Investor Forum

- Public Offer Documents

- Annual Report & Financials

- Investor Presentation

- Transcript

- Shareholding Pattern

- Press Release

- Policies

- Board & Committee Details

- Contact for Investor

- Media Coverage

- SEBI Circular

- Compliance Under Regulation

- Stock Exchange Fillings

- Annual Return

- Annual Secretarial Compliance Report

- Investor Information

- CSR Report

- News Paper Advertisement

- Events

- Get in Touch

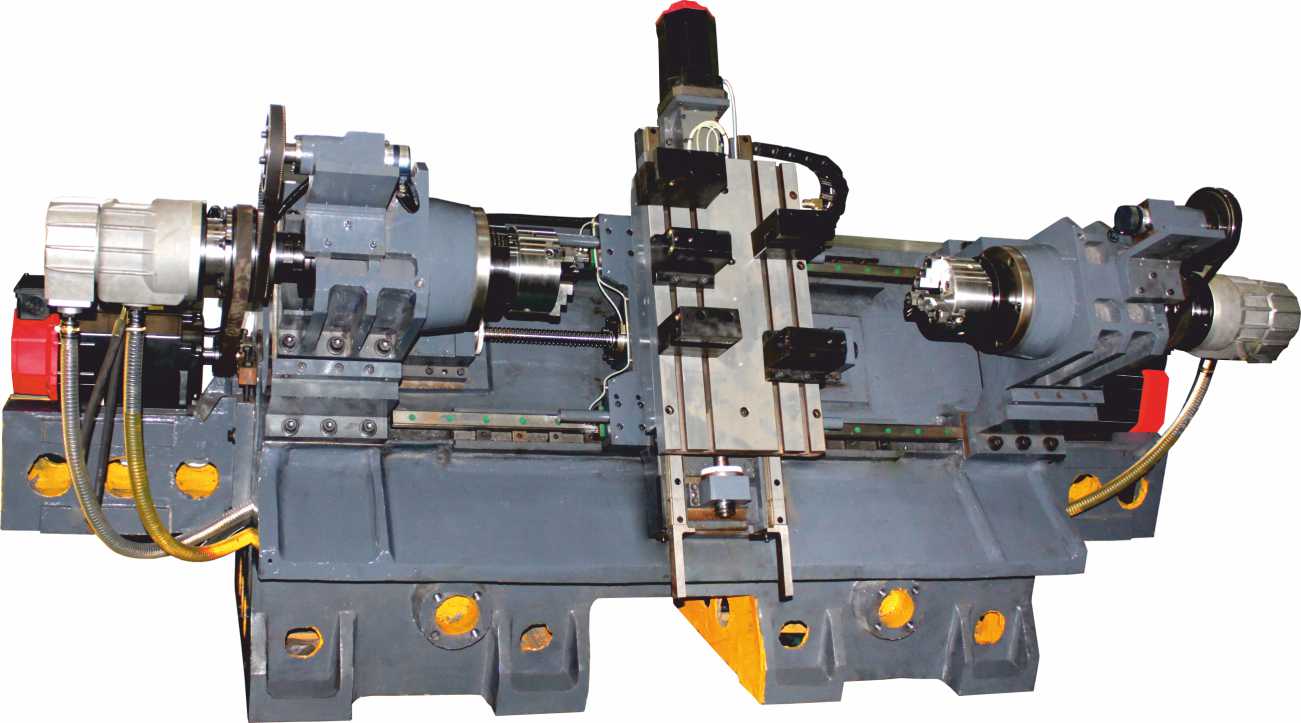

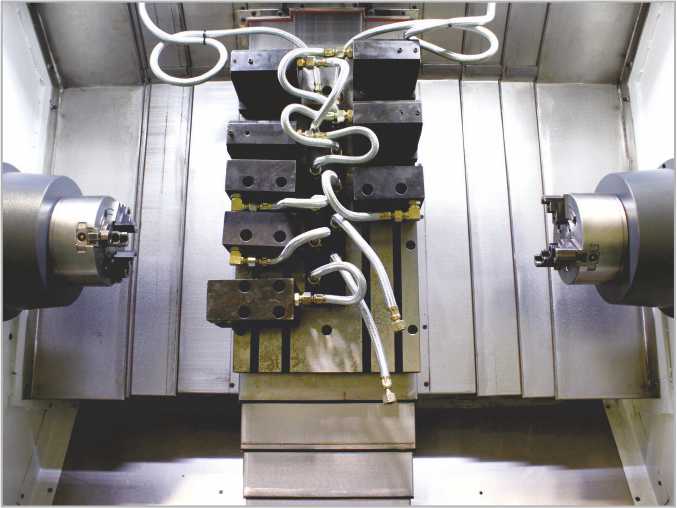

Spindle

The spindle is of cartridge type design and uses 3 super precision angular contact bearings at front and 2 angular contact bearings at rear end. The bearing configuration gives high stiffness to the spindle assembly in both axial and radial direction.