- Home

- About Us

- Infrastructure

- Products

- Investor Forum

- Public Offer Documents

- Annual Report & Financials

- Investor Presentation

- Transcript

- Shareholding Pattern

- Press Release

- Policies

- Board & Committee Details

- Contact for Investor

- Media Coverage

- SEBI Circular

- Compliance Under Regulation

- Stock Exchange Fillings

- Annual Return

- Annual Secretarial Compliance Report

- Investor Information

- CSR Report

- News Paper Advertisement

- Events

- Get in Touch

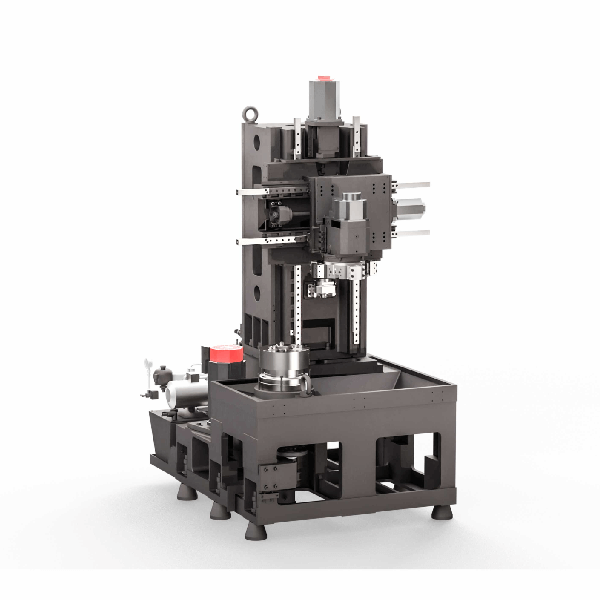

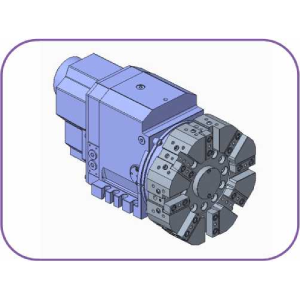

High Capacity Accurate Spindle

The cartridge type high precision spindle is supported by the double row cylindrical roller bearing and bi-directional angular thrust bearing. Radial and axial loads are accommodated individually. The bearings are grease lubricated for life. The high torque, constant power supplying AC spindle motor minimizes spindle acceleration/deceleration rate, also enabling strong machining ability.