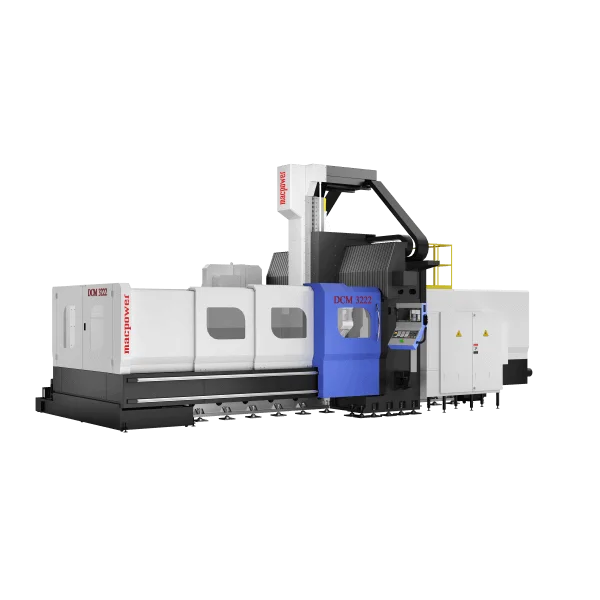

DCM Series

Double Column Machines

DCM Series

Model Variants

- DCM 2216

- DCM 3216

- DCM 3222

- DCM 4222

In today’s competitive market, you need robust Double column machine with un-compromised performance and specifications to produce world class products quickly accurately and with minimum non productive time.

Overview

Structure & Frame

The rigid bed and step up structure are made out of grade 25 cast iron for more stability. It is ribbed to provide more rigidity and less distortion during cuts and faster production, with virtually no vibration. A totally revamped ergonomic structure and frame helps stabilise different machining operations with requisite precision.

High Capacity Accurate Spindle

The precision cartridge spindle unit having three super precise angular contact bearings at front and two at rear end, this combination ensures higher stiffness. Bearings are perfectly aligned and grease packed for long life. Spindle is indirectly driven by high speed AC spindle motor with reduced pulley ratio, to achieve high spindle torque and optimal performance of machine.

Advance Inspection Technology

Laser Calibration is carried out to insure the linear accuracy, providing accurate compensation for pitch and backlash. The machine facilities the attainment ofpositional accuracy up to 0.01 mm / 300 mm and repeatability accuracy up to 0.007 mm.

Heavy Duty Roller LM Guideways

All axes are furnished with precise and heavy load capacity re-circulating LM guide ways enabling high acceleration-de acceleration and hence better rigidness.

Double Anchored Ball Screws

Ball Screws are directed by direct coupled AC servo motor with flexible coupling. This greatly improves positioning accuracy, and provides more accurate threading and contouring. Ball Screws are anchored at both ends and inspected for parallelism with axis guide. Pre-loaded ball nuts eliminate backlash.

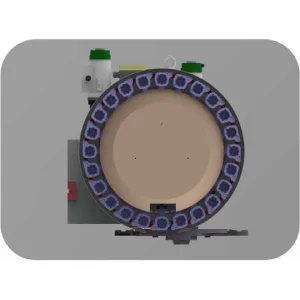

Reliable Turret

Twin arm type side mounted ATC driven by screw and cam speed up tool changing time with random access and resulted in reduce cycle time and higher productivity. Each subsystem is tested for innumerable cycle at every stage to enhance reliability.

Standard Accessories

- ROLLER GUIDEWAYS

- WORK LIGHT

- HAND WHEEL

- LEVELING PAD

- RING COOLANT

- AIR GUN

- CENTRALIZED LUBRICATION SYSTEM

- PULL STUD

- DRY AIR CUTTING

- COOLANT GUN

- SCREW CONVEYOR TWIN TYPE

Optional Accessories

- AUTO DOOR

- LINEAR SCALE

- STABILIZER

- FLUSH COOLANT

- COOLANT THROUGH SPINDLE

- ROTARY TABLE

- ROTARY TILTING TABLE

- GEAR BOX

- HIGHER RPM SPINDLE

- SPINDLE CHILLER

- TOOL PROBE

- WORK PROBE

- TOOLED UP SOLUTIONS

- CHIP CONVEYOR

- 90 MILLING HEAD (AUTOMATIC & MANUAL)

- AC SWIVELING HEAD (AUTOMATIC & MANUAL)

Technical Specifications

Capacity

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| Travel X | mm | 2200 | 3200 | 3200 | 4200 |

| Travel Y | mm | 1600 | 1600 | 2760 | 2760 |

| Travel Z | mm | 800 (1000) | 800 (1000) | 800 (1000) | 800 (1000) |

| Distance Between Column | mm | 1700 | 1700 | 2500 | 2500 |

| Rapid X/Y/Z | m/min. | 20/20/15 | 15/20/15 | 15/15/15 | 15/15/15 |

| Distance Table - Spindle Face | mm | 200 - 1000 | 200 - 1000 | 200 - 1000 | 200 - 1000 |

Table

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| Size | mm | 2200X1300 | 3000X1300 | 3000X2000 | 3500X2000 |

| T Slot No | - | 9 | 9 | 12 | 12 |

| T Slot CD | mm | 125 | 125 | 160 | 160 |

| T Slot Width | mm | 18 | 18 | 22 | 22 |

| Max. Safe Load on Table | Kg | 6000 | 8000 | 10000 | 10000 |

| Distance Table - Spindle Face | mm | 200 - 1000 | 200 - 1000 | 200 - 1000 | 200 - 1000 |

Spindle

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| Taper | - | BT - 50 | BT - 50 | BT - 50 | BT - 50 |

| RPM | - | 80 - 6000 | 80 - 6000 | 80 - 6000 | 80 - 6000 |

| Cutting Feed Rate | mm/min. | 1 - 10000 | 1 - 10000 | 1 - 10000 | 1 - 10000 |

| Spindle Motor - Fanuc | Kw | 18.5 / 22 | 18.5 / 22 | 18.5 / 22 | 18.5 / 22 |

| Spindle Motor - Siemens | Kw | 21.5 / 32.3 | 21.5 / 32.3 | 21.5 / 32.3 | 21.5 / 32.3 |

Automatic Tool Charger

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| No. of Tools (Std/Opt) | - | 24 (30/40) | 24 (30/40) | 24 (30/40) | 24 (30/40) |

| Max. Tool Dia. (All pocket full) | mm | 125 | 125 | 125 | 125 |

| Max. Tool Dia. (Adj. pocket empty) | mm | 220 | 220 | 220 | 220 |

| Tool Length Max. | Kw | 400 | 400 | 400 | 400 |

| Tool Weight Max. | Kg | 20 | 20 | 20 | 20 |

Accuracy

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| Positional Accuracy | mm | 0.020 | 0.020 | 0.020 | 0.020 |

| Repeatability | mm | 0.008 | 0.008 | 0.008 | 0.008 |

Chip Removal

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| Chip Removal | - | Screw Conveyor + Chip Tray | Screw Conveyor + Chip Tray | Screw Conveyor + Chip Tray | Screw Conveyor + Chip Tray |

| Machine Weight | Kg | 25400 | 27350 | 33900 | 35900 |

System

| AXIS CAPACITY | UNIT | DCM 2216 | DCM 3216 | DCM 3222 | DCM 4222 |

|---|---|---|---|---|---|

| Fanuc | - | Oi MF Plus | Oi MF Plus | Oi MF Plus | Oi MF Plus |

| Siemens | - | 828D | 828D | 828D | 828D |

| Mitsubishi | - | M80V | M80V | M80V | M80V |